Tadek delivered an IAC systems FEED design for a FOW array for an important client. A project bolstered by the expertise of Tadek’s new Senior Marine Analysis Engineer Bijesh Chenna Kandathil.

Delivering an IAC system FEED design report for a 50MW floating offshore wind farm

After weeks of collaboration, detailed engineering analysis, concept optioneering and project engineering, the team delivered an IAC system FEED design report for a 50MW floating offshore wind farm.

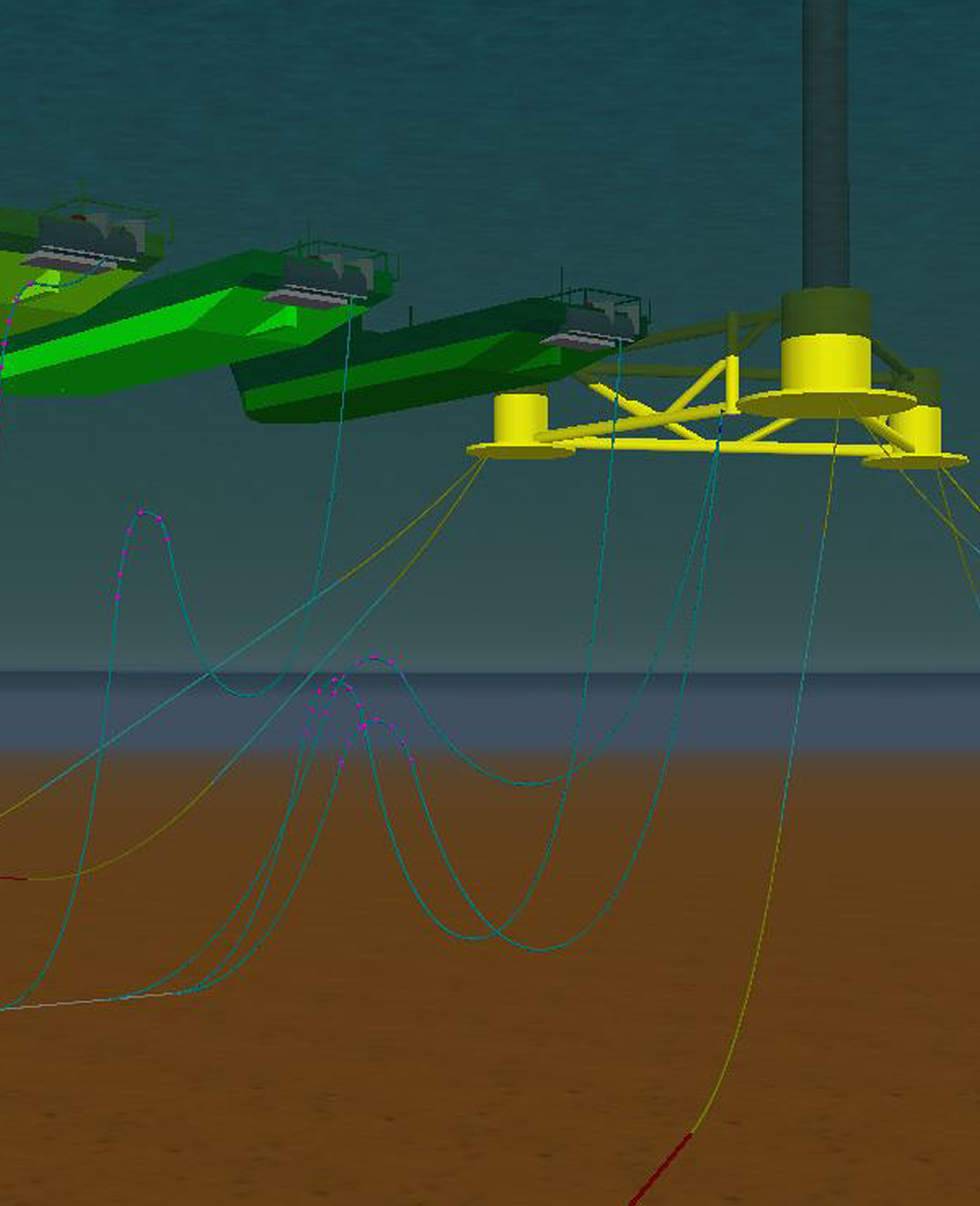

The preliminary design of the configuration involved initial quasi-static analysis of the inter-array cable, with the platform fixed at the maximum excursion based on the environmental heading. Whilst fixed in this position, the platform is exposed to an extreme sea-state. Each of the configurations (lazy wave, steep catenary, pliant wave, steep wave) were tested in the same conditions. Dynamic analysis was carried out for selected configurations (DLC 6.1 & DLC 6.2 – Ultimate Limit State, parked, DLC 1.6 – Power Production in severe sea state and DLC 10.2 – Accidental Limit State, loss of mooring line). The cable is also assessed in the static and normal operating condition. As well as the principal load cases, further sensitivity analysis was carried out based on wave direction, degradation of buoyancy, and marine growth.

The design of the IAC subsea configuration also closely considered the installation process

The design of the IAC subsea configuration also closely considered the installation process. Each iteration of the design must be sequenced to show the key steps and whether it is feasible to install the system without unacceptable risk. The IAC approach and exit directions on each platform were decided based on cable interference and installation considerations. IAC azimuth angles were proposed such that the cable’s approach and exit were always on opposite sides of the platform. This ensured there is minimal interference or clashing between the cables. From an installation perspective, the cable layout provided sufficient cable/mooring line footprint-free seabed area for the initial pay-out required during a second end cable pull-in operation.

Andrew Wright commented on the work:

Utilising the experience and expertise across the team, this project was a perfect synergy between the Tadek project engineers, naval architects and marine analysis engineers.

The project was a perfect synergy of Tadek’s expertise. Project engineers, familiar with developing installation procedures for FOW, floating system hook-ups and cable lay works, worked seamlessly with the naval architects and marine analysis engineers.

Andrew Wright, Naval Analysis Engineer