Interesting post from Sealip, and great to see that #Orcina has developed. This type of analysis is great but not new, albeit it looks very pretty now in the OrcaFlex GUI. At Tadek, we’ve been implementing our own equivalent methods for 15 years to account for the more complex flow fields, as this has always been part of the standards.

We agree that the ‘Tabular Current’ functionality introduced with OrcaFlex 11.5 gives considerable flexibility to include fluid-structure interaction near monopiles more accurately. While combining current amplification and wave kinematics into a single time history makes the simulation look cool, the approach is highly inefficient.

At Tadek, we’ve developed a methodology used across multiple CPS design projects that includes these effects in a far more efficient way. By treating near-structure current amplification, wave kinematics modification, and monopile wake effects separately, analysts gain more control in tuning models, and environmental parameters can be adjusted easily. This also improves computational efficiency, using tabular current, sea-state RAOs, and wake generation modules on OrcaFlex.

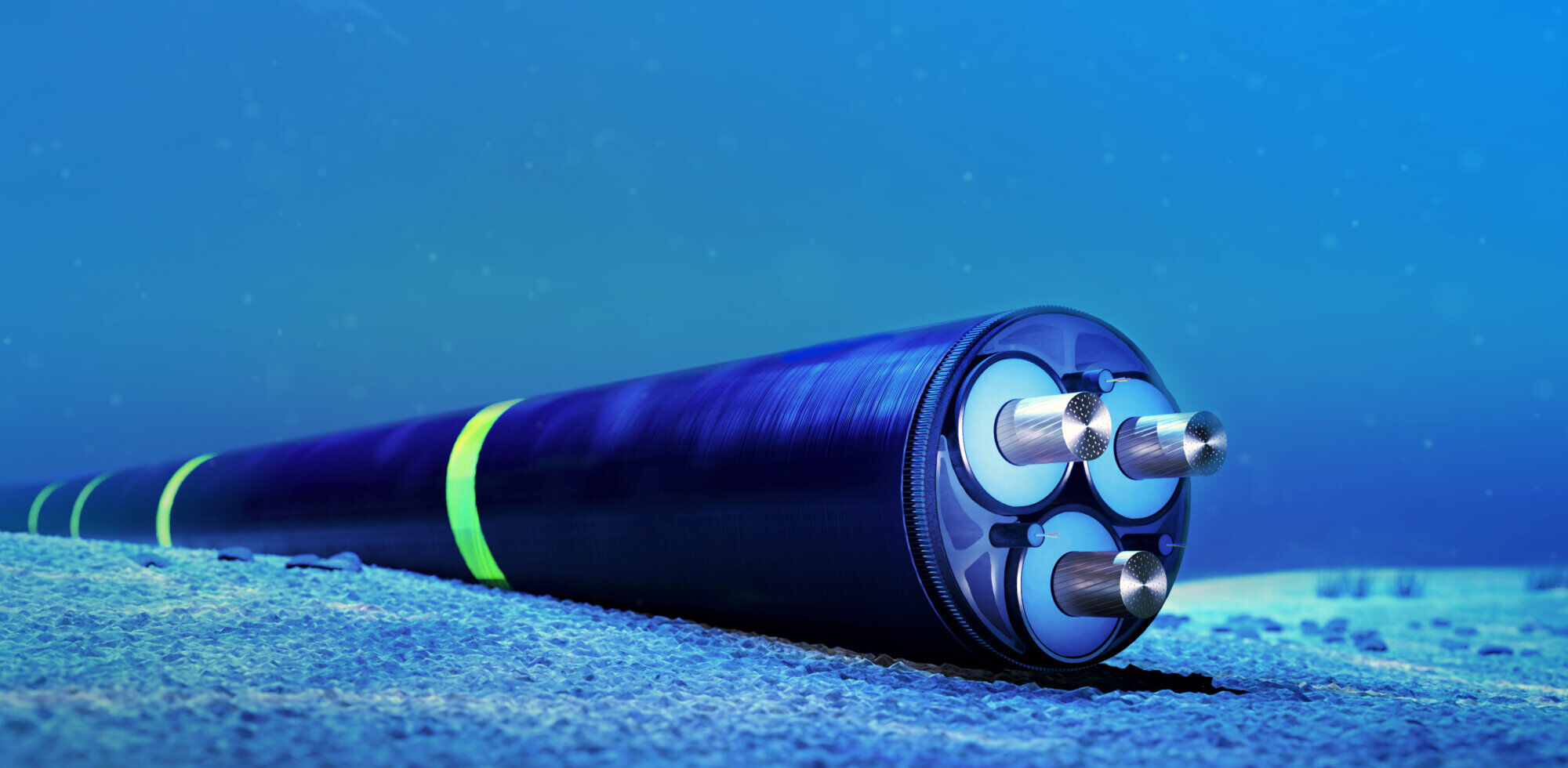

Beyond Simulation: Addressing the Real Causes of CPS Failures

While we support improving accuracy in subsea cable and CPS modelling, we don’t believe that inclusion (or exclusion) of these effects is a silver bullet for understanding CPS failures.

Realistically, there are few — if any — failures due to ULS events. Most issues stem from fatigue and free span motion, where operational lifetime predictions are typically very clear pass/fail scenarios. These outcomes rarely depend on inclusion of wave flow amplification or other commonly debated modelling assumptions.

Tadek agrees that the historical lack of FEED studies and insufficient understanding of cable and CPS behaviour has hindered the performance and development of offshore wind farm systems.

To prevent this from continuing, industry-wide collaboration and better integration are essential, so that:

-

Developers don’t compromise operators by thinking only in CAPEX terms

-

Cable manufacturers set clear fatigue expectations, especially for static designs in dynamic environments

-

CPS manufacturers prioritize technical suitability over cost

-

Installers aren’t pushed into a race to the bottom, which leads to inadequate CAPEX-driven solutions

A Call for Smarter Investment and Collaboration

The number of variables affecting cable and CPS analysis is large and any of them can significantly impact results. Whether it’s accurate non-linear bend stiffness, realistic fatigue curves, or applying the right standards, it’s clear that greater collaboration and FEED investment are critical to improving offshore wind performance.

About Tadek Ocean Engineering

Tadek offers services in SURF & Marine Analysis, FOW & Floating Systems Design, Structural Design, Naval Architecture, and project engineering & project management support to Marine Projects.

We work collaboratively as a trusted partner, dovetailing with stakeholders and project teams, providing specialist consultancy, complex analysis, engineering solutions, and practical project delivery.

Our expertise has benefited over 300 successful projects worldwide, supporting a wide range of requirements from high-value corporate projects through to prototype works.